United Kingdom

Processing Skids for

Water Deaeration and Purification, Multi-stream Fluid Blending, Carbonation and Gas Injection

©Copyright 2012 - Centec UK - All rights reserved

Info@centec-uk.com www.centec-uk.com www.centec.de

Meeting Customer Preferences - Centec are a well established and flexible independent engineering company who strive to provide the best technical solutions while where possible complying with customer specific preferences for site standard equipment.

Process Sensors:

Centec’s sensor division in Frankfurt are a pioneer in intelligent product sensing equipment. Today Centec are a leading manufacturer of high accuracy sensors to monitor oxygen content, sound velocity/product concentration, product density, as well as alcohol and dissolved gas measurement. This real-world experience enables Centec to manufacture their systems with a level of knowledge and expertise that very few process engineering companies can hope to attain. However if customers for Centec Systems have standardised on or prefer to use equipment made by other sensor manufactures, then provided they are suitable for the task they can normally be used on Centec skids. For more details please visit: www.centec-sensors.co.uk

Process Sensors:

Centec’s sensor division in Frankfurt are a pioneer in intelligent product sensing equipment. Today Centec are a leading manufacturer of high accuracy sensors to monitor oxygen content, sound velocity/product concentration, product density, as well as alcohol and dissolved gas measurement. This real-world experience enables Centec to manufacture their systems with a level of knowledge and expertise that very few process engineering companies can hope to attain. However if customers for Centec Systems have standardised on or prefer to use equipment made by other sensor manufactures, then provided they are suitable for the task they can normally be used on Centec skids. For more details please visit: www.centec-sensors.co.uk

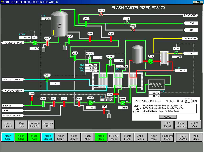

Centec MCM ‘Modular Concentration Monitors’ can receive and process signals from many different sensors. An MCM processes the signals and provides comprehensive data about various product characteristics and process conditions. MCM units are commonly used on Centec blending systems. In addition Centec also design and engineer their systems to use most of the major process automation equipment, as requested by the customers. This can include Siemens, Alan Bradley, Rockwell, Omron, Mitsubishi, etc and the common network protocols such as ControlNet, Profibus etc. Conversely an instrument rack and Functional Design Specification (FDS) can be provided for customers who prefer a more DIY approach.

Some customers have preferences for particular equipment on their site, be for compliance with group standardisation, to minimise spares holding or to help maintenance technicians. Centec will always try to comply with customer requests for equipment such as valves, pumps, heat exchangers etc where it does not compromise the performance of the Centec system. In general Centec use well proven and trusted German manufacturers of components on their skids.

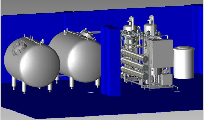

Centec use some of the latest 2D and 3D CAD software in the design of their skids. It can also be used to visualise site installation conditions. Every project is different, some have significant space restrictions, access limitations or drainage problems for example. It is essential that customers make Centec fully aware of any specific issues on their site and that they carefully check drawings etc for any potential discrepancies. Where appropriate 3D drawings can be provided to clients.

Links to PDF Library

Sensors, Automation and Mechanical Equipment